While the Chinese steel sector is by far the largest in the world today, India is poised to occupy the next position in the near future. India now represents one of the fastest growing economies in the world and there has been a rapid growth of steel consumption and production. However, the strides on the steel manufacturing front need to be considered along with sustainability aspects; the latter taking into consideration the optimal use of the raw materials, the handling of environment-degrading solid / liquid wastes and gaseous emission, as well as conversion of wastes into value-added products.

The world has seen a phenomenal growth in the steel industry over the past two decades contributing to the upward movement in the economy. While the Chinese steel sector is by far the largest in the world today, India is poised to occupy the next position in the near future. However, in order that the carbon foot-print is manageable and the environment reasonably clean, the industry has to look into several factors, including newer, greener technologies some of which are just emerging in the horizon, along with modifications in the existing processes for conserving raw material and energy resources. It would not be easy to retrofit some of the new technologies with the existing, conventional processes. Equally significant, the economic viability of the steel industry if they were to adopt the process-changes. The Governments in many countries are also examining framing more stringent regulations keeping the environment in view. Thus, the future of the steel industry appears quite challenging; more so in countries such as India that is about to embark on an ambitious plan for economic growth.

General

In all industrial operations, environmental management is an important consideration since the well-being of the society as a whole, is involved. In today’s world, extensive use of steel is quite common and therefore issues associated with environment in the manufacture and use of steel assume great importance. The issues relating to environment in steel plants relate to a wide range of items : air–emission; solid wastes; waste water, noise and hazards and so on.

A critical example of acute degradation of environment associated with air emission is global warming, through what is commonly known as the Green House Effect (GHE). This nomenclature comes from the cold countries where glass houses are constructed in farms to prevent plants from withering due to severe cold, by preserving heat inside the enclosure (it is known that glass cover would allow the short wave length heat radiation to come through, while the radiation from the plants that are of longer wave length cannot escape out through the glass and is retained inside).

The Green House Effect has had a severe environmental impact, particularly during the past two decades and is threatening the entire human race with multiple catastrophes, one of them being the rise of sea-level (through the melting of glaciers), another could be that several areas on the surface of the earth could be rendered unfit for habitation by extreme rise in temperature over sustained periods that in turn would change natural vegetation affecting crop production, extinction of species and so on. One of the major causes of the GHE is the rise in the content of gases that are labeled as Green House Gases ( CO2, CO, CH4, N2O, CF4 etc. and the ozone depleting gases such as CFCl3, CF2Cl2, CClF3 etc. ). The quantity of carbon dioxide (CO2) generated in various common industries has made it a critical menace facing the modern society. Carbon dioxide is generated in power (particularly, thermal power) plants; cement plants; metallurgical industries and so on. Therefore, methods to control the emission of CO2 in the industries in general, and steel industry in particular, have engaged the attention of experts from industry as well as from academia. It may be remembered that while CO2 and other harmful gases are generated through various processes of iron & steel making in the steel plants; these are generated also from the power plants that supply power to steel plants and therefore make indirect contribution to the total CO2 associated with steel industries.

In addition to the above, the integrated steel industries have to deal with a great deal of solid wastes in the steel manufacturing plants (e.g. slags from iron making and steel making; sludges; scales and dust etc. ); at the various mines ( the ore fines, slimes in the tailing ponds at the washeries / beneficiation plants and the coal and lime fines etc.). The waste water includes the effluent streams in cooling water, rinse water and several different process effluent streams. Steel manufacturing facilities also generate noise from various sources including scrap and product handling; waste or by-product gas fans; process cooling and draft fans; rotating equipment in general; de-dusting systems; furnace charging; EAF melting processes; fuel burners; cutting activities etc.

India now represents one of the fastest growing economies in the world and along with that, there has been a the rapid growth of steel consumption and production. However, the strides on the steel manufacturing front need to be considered along with sustainability aspects; the latter taking into consideration the optimal use of the raw materials used in steel making ( so that these valuable non-renewable materials are conserved and last longer ); the handling ( including re-cycling ) of environment-degrading solid / liquid wastes and gaseous emission, as well as conversion of wastes into value-added products.

The above items would be dealt with, briefly in the following, after putting the iron and steel scenario in perspective.

Iron & Steel Production Scenario in India

The world steel output during 2012 was recorded at 1545 mt ; the magical figure of 1500 mt having been surpassed the previous year ( it was 1536.98 mt in 2011). All these improvements in production have been witnessed over the past two to three years after it was severely affected by the economic down-turn in the year 2009 when the total crude steel production had dropped to 1237 mt from a figure of 1342 mt the year before. Equally significant, China produced 716.5 mtpy, accounting for about 48 percent of the world output of steel and that over the past ten years it has registered a growth even during the recession period. Further, the continuous casting route accounts for over 95 % of the total crude steel in the world while in China it is over 98 %, indicating that there is an appreciable reduction in the energy front for processing of steel.

As for the steel industry in India, with a crude steel production of around 77.5 mt in 2012 it occupies the fourth position, behind China (716.50); Japan ( 107.2) and the U.S. ( 88.9). The CAGR of the steel industry has been over 8.3 % and is expected to be higher in the coming years. India is projected to occupy the second position, only behind China, in the next 3 to 4 years. India’s consumption of steel is rising and in order to meet the gap between the production and consumption, around 7 mt of steel were imported in 2012. Unfortunately, continuous casting ( CC ) route accounts for only 80.3 % ; the lowest among the large steel producing countries ( China, Japan, U.S. and S.Korea ), and the ingot production is still quite high. However, there is a steady rise in the CC – route and it is expected that all new capacity additions would be only through this route. India is projected to become the second largest steel producer, only behind China, in the next 3 – 4 years. One other important index of growth of a country is the per capita steel consumption. While the world average is around 250 kg. per person, the Indian figure is a dismal 56 kg ( China’s figure is over 400 kg ). This points to the fact that there is an appreciable growth potential in India.

A large number of MoUs progressing in various provinces, Orissa being the most prominent, India would have a planned capacity of around 276 mt around 2020. One of the features of this growth has been the increasing importance of the electric furnace route ( accounting for a share of over 52 % in 2009 ), over the more conventional BF-BOF route. Within the basket of the electric route, the electric arc and the induction furnace account for near equal shares.

India has also emerged as the world’s largest producer of sponge iron, accounting for over 20 mt / yr. The share of coal-based sponge route to the gas-based route has been roughly 70: 30. The capacity for sponge iron making has also increased over the years and stands at 32 mt / yr .. Thus, the scope to enhance the sponge iron production even further, exists in the country, provided the manufacturers find the price lucartive. The strong sponge-iron production base has helped the steel sector, in particular the electric steel sector, overcome the acute shortage and the steep rise in price of the steel scrap.

Post-liberalisation, India has also become a major producer of pig-iron for sale within and outside the country, the total production for sale having been around 6 mt.

Raw Material Requirement & Conservation

The integrated steelmaking route, based on the blast furnace (BF) and basic oxygen furnace (BOF), uses raw materials including iron ore, coal, limestone and recycled steel. On average, this route uses 1,400 kg of iron ore, 770 kg of coal, 150 kg of limestone, and 120 kg of recycled steel to produce a tonne of crude steel. Thus for every tone of crude steel, one requires a total of 2.5 tonnes of solid raw materials for the BF-BOF route.

The electric arc furnace (EAF) route, based on the EAF, uses primarily recycled steels and/or direct reduced iron (DRI) and electricity. On average, the recycled steel-EAF route uses 880 kg of recycled steel, 150 kg of coal and 43 kg of limestone to produce a tonne of crude steel.

In India, the iron ore production is expected to grow from the current value of about 115 mt. to 206 mt by 2017; the coking coal requirement from ~ 43 mt to 90 mt. and other ores ( manganese, chromite, ferro-chrome, ferro-manganese, silico-manganese, ferro-silicon, coal for injection and refractories etc. ) from ~ 11 mt. to 22 mt. in the same period.

Necessity of Beneficiation and Agglomeration for Conservation of Iron Ore

For meeting the needs of the projected figure of around 200 mt of steel in 2020, one would need about 380 mt of iron ore per year. Assuming that the export would be increased to around 120 mtpy, India would be required to produce 500 mt / yr. of raw iron ore. Thus, at the mines with a cut-off at 56 % Fe, the iron ore reserves of around 25, 000 mt in the country would last only 50 years. However, with the export policy revised ( for conserving indigenous ore ), one would be able to extend the same. More importantly, by lowering the cut-off to 45% Fe content, the reserves can go up by another around 30 %, thus contributing to extending the life of reserves.

The above operation would however requoire beneficiation of the low-grade ore, also of fines ( used in sinter ) in order to bring up the Fe – content to around 65 %, and equally important, reducing the alumina content to below 1.6 %(from over 3%), impacting the productivity increase of blast furnace. This would also reduce the phosphorus content, improving the quality of iron.

The beneficiation of iron ore using several techniques such as spirals, floatex density separators, jigs, multi-gravity separator, low and high intensity magnetic separator, conventional as well as column flotation, selective dispersion – flocculation etc. which are all part of current practice. The huge quantities of iron ore slimes ( size < 0.15 mm ) collected in tailing ponds, estimated to be 130 mt (accumulate to the tune of around 10 mt/yr.) are not being utilised today. However, by using newer techniques such as Batac jigs, packed flotation column, packed column jigs and centrifugal concentrators like Falcon Concentrator, Kelsey jigs, Knelson Concentrator etc. for the beneficiation of iron ore slimes, it may be possible to add a sizeable proportion to the iron ore production. One needs to adopt a holistic approach and develop complete flow-sheets to deal with specific iron ores.

Pelletising as a Means of Utilising the Fines

Low grade iron ore, iron ore fines and iron ore tailings/slimes accumulated over the years at mine heads and generated during the existing washing processes, need to be beneficiated to provide concentrates of required quality to the Indian steel plants. However, these concentrates are too fine in size to be used directly in the existing iron making processes. For utilizing this fine concentrate, pelletization is the alternative available. Pelletizing turns very fine-grained iron ore into balls which are suitable for blast furnace and direct reduction ( sponge iron production ). Pellet plants can be located at mines, near harbours or be attached to steel mills. Due to their high strength and suitability for storage, pellets can be easily transported over long distances, with repeated transshipments if necessary. The pellets can be used in blast furnaces due to good reducibility, high bed permeability, uniform porosity (25-30%): lower heat consumption than sinters, uniform chemical composition & very low LOI, as well as ease of handling and transportation. The Indian Blast Furnaces that had earlier used only sized ( lumpy ) ore and sinters are now geared up to using pellets as well , thus using a 3-componenet burden in stead of conventional 2-components . This is a significant change in the Blast Furnace operation in India. Thed sponge iron units are also preparing themselves to using this input, thus reducing the cost of production, apart from contributing to environmental improvement.

Coal Injection as a Means of Conserving Metallurgical Coal & Reducing Pollution

Coke, made by carburising coal (i.e. heating in the absence of oxygen at high temperatures), is the primary reducing agent of iron ore. About 30% of coal can be saved by injecting fine coal particles into the blast furnace, a technology called Pulverised Coal Injection (PCI). One tonne of PCI coal used for steel production can replace about 1.4 tonnes of coking coal. Coals used for pulverised coal injection into blast furnaces have more narrowly defined qualities than steam coal used in electricity generation. Global steel production is dependent on coal – around 68% of total production relies directly on the input of coal. 761Mt of coking coal and Pulverised Coal Injection (PCI) coals are used in global steel production, which is around 12% of total hard coal consumption worldwide.

Tata Steel was the first steel plant that started injecting pulverized coal into some of its blast furnaces; thereby saving the costly metallurgical coal and coke-making operation ( energy saving and environment-friendly). This practice is becoming wide-spread.

Environmental Aspects in Steel Plants

A typical integrated steel plant includes several operational units, such as a sinter plant ( for making burden for blast furnace using fines), coke-oven (for converting coal to coke), lime calcining plants, blast furnace (for pig iron), steel making shop ( for converting pig iron to steel), continuous casting ( of billets/ blooms/slabs etc. ), rolling mills ( hot / cold ); coating units ( e.g. galvanizing ) etc.

As mentioned earlier, the environmental issues in the iron and steel sector primarily relate to the air-emission; solid wastes; effluent water and noise. There are a number of organizations and agencies that are concerned with creation of yard-sticks for the ‘safe’ operation of the individual units of integrated / secondary steel mills. Consequently, procedures have been evolved for measurement of various parameters and for setting targets.

For example, the Life Cycle Assessment ( LCA ) by the International Iron and Steel Institute ( IISI ), attempted to inventorise inputs and outputs in terms of raw materials, energy and emissions that is shown schematically . This analysis also made use of a software called TEAM ( tools for environmental analysis and management ), developed by Ecobilan, France and was adopted by several steel companies in Europe and Japan, apart from the IISI. Three large integrated steel companies in India (Tata Steel; RINL and BSP ) also made use of the same software introduced under a programme funded by the Ministry of Environment & Forest and coordinated by the author, while at Tata Steel in the late nineties. This software was adopted for estimating the raw materials, energy and emissions, as well as for estimating the equivalent CO2 emissions in the various operating units of an integrated steel plant.

The International Finance Corporation ( IFC ) and the World Bank Group have together brought out a set of Environmental , Safety and Health (ESH) Guidelines, for integrated and secondary steel mills, that were introduced in July 1998 and have been updated in April 2007. Some of the salient features of the same shall be dealt with, below.

Gaseous Emission

Under the air emissions, the guidelines cover those from the various operating processes involved in the steel plant as well as those generated by captive power plants fuelled by the product gases ( e.g. coke oven gas, BF gas and BOF gas ). In each of the process steps, the emissions may contain varying concentrations of mineral oxides, metals (e.g. arsenic, cadmium, mercury, lead, nickel, chromium, zinc, manganese), and metal oxides. Measures have been recommended for each of the process steps for reducing the emission of particulate matter (PM). Likewise, recommended practice for reducing NOx ( nitrous oxides ); SO2 (sulphur dioxide); CO (carbon monoxide); chlorides & fluorides; dioxins & furans; and CO2 (carbon dioxide) etc. have also been made in these guidelines.

Gases produced during steelmaking are fully reused as an energy source either in the blast furnace and reheating furnaces or in power generation plants within the steelworks, saving fossil fuels. Coke oven gas contains about 55% hydrogen and may prove an important hydrogen source in the future.7

It may be recalled that CO2 emission rates were menacingly high at over 3 t/tcs ( tonne per tonne of crude steel ); currently this rate is just over 2 t/tcs – a substantial reduction, however is still quite high.

ULCOS Programme

To reduce the carbon dioxide level substantially, a major effort taken up as international collaboration with IISI is the Ultra Low Carbon Dioxide Steelmaking (ULCOS) programme that started in Europe and now other countries have joined in. In Europe, some 48 organisations from academia, industries and research laboratories joined the consortium. In 2008,The European Steel Technology Platform (ESTEP) decided to launch a second phase of the Ultra Low CO2 Steelmaking research programme. ULCOS-II will be the world’s most ambitious Research and Development (R&D) effort to reduce process-related CO2 emissions in steelmaking. The next phase will require significant levels of investment – the first industrial-scale demonstration is estimated at €300 m. There are many sub-programmes under ULCOS; however there are two main directions: (i) capturing the CO2 being emitted in various sections of a steel plant and storing them ( e.g. sequestration, which is of several kinds ) and using them subsequently, (ii) producing power utilizing the pressure difference between gas issuing from a blast furnace and the gas-holder. This has already taken place in a few plants, (iii) replacing the carbon by hydrogen as the major reductant for iron oxide. This is however going to take some time before commercialization.

Solid Wastes

The most voluminous ‘solid wastes’ generated in a steel plant are the slag at the blast furnace (BF) and steel making shops (BOF / EAF). The actual quantities vary depending upon the nature of raw materials used ( therefore the gangue needs to be taken out as slag ). The amount of slag at the BF is around 300 – 400 kg / t of pig iron; the quantity of BOF slag is 100 – 150 kg / t crude steel and in the EAF one may come across 150 – 200 kg / t of crude steel.

Most solid waste residue from the integrated iron and steel sector is recycled to obtain added value from various types of byproducts, slag, scales and dust. Waste materials may include slag from BF; fine dust and sludge from BF gas cleaning; fine dust from BOF gas cleaning; BOF slag; high alkali chlorides and heavy metal chlorides from the last field of electrostatic precipitators; and treatment of the off-gas from sinter strands. The slag from BF is today utilized extensively in cement industry after granulation; that from the steel melting shop ( BOF ) is used conventionally as fertilizer due to its high phosphorus content. Several newer uses of this slag are now there, including in the cement industry owing to high free lime content.

Pickling acid regeneration sludge can be recycled in steel plants (EAF and blast furnace) or processed for the production of iron oxides. The iron oxide from hydrochloride acid regeneration can be used in several industries as a high quality input (e.g. production of ferromagnetic materials, iron powder, or construction material, pigments, glass and ceramics).Sludge from wastewater treatment may contain heavy metals (e.g. chromium, lead, zinc, and nickel) and oil and grease. Part of the sludge from wastewater treatment may be internally recycled or else deposited in special landfills. Sludge re-use may require a pre-treatment stage, which typically consists of pressing, drying, and granulation etc.

Decommissioning wastes in steel manufacturing facilities may include insulation materials containing asbestos, as well as contaminated soil and groundwater media from areas such as the coal storage stockpiles, the coke oven and coke oven gas treatment plant. Recommendations on the management of waste materials, decommissioning activities have been provided in ESH guidelines.

Waste Water

Cooling water, rinse water and process water from various operational units constitute waste water in a typical integrated steel plant. While cooling water is recycled, rinse water may contain various suspended solids, dust, lubricating oil or other pollutants; hence needs to be treated for re-cycling. The process water from specific operation units such as coke ovens; pickling plants or rolling mill etc. need require special treatments Thus, ammonia is reduced through air stripping, while the toxic organic such as phenol is removed through biological treatment and heavy metals are removed by chemical precipitation / coagulation / flocculation etc. Since water is going to be increasingly scarce, it is necessary to conserve this commodity

Noise

Integrated steel manufacturing facilities generate noise from various sources including scrap and product handling; production units (e.g. BF, BOF, EAF etc.), waste or by-product gas fans; process cooling and draft fans; rotating equipment in general; de-dusting systems; furnace charging; fuel burners; cutting activities, transport and ventilation systems etc.. Specific recommendations have been made with regard to noise reduction by the World Bank Group.

General Hazards

There are specific occupational health and safety issues related to steel manufacturing activities, these include: Physical hazards, Heat and hot liquids, Radiation, Respiratory hazards, Chemical hazards, Electrical hazards; Fire and explosions etc. Specific measures have been suggested for each by the guidelines.

Broad Indicators of Pollution in Steel Plants

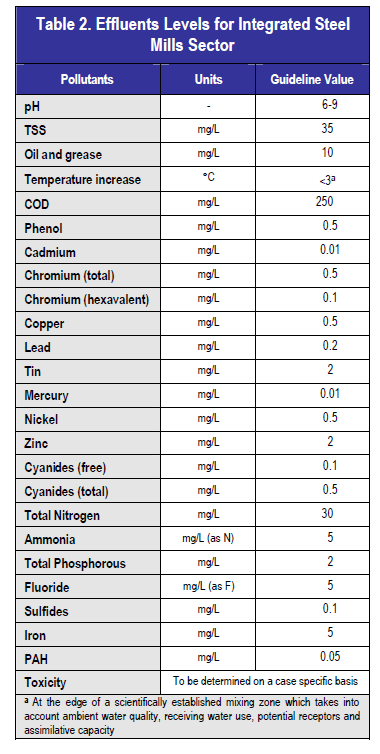

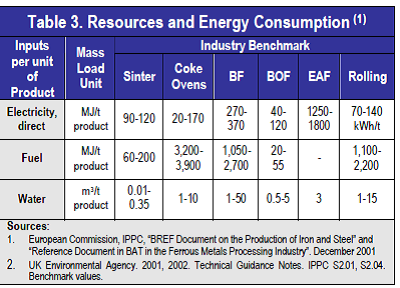

Target values for process emissions, effluents, resources and energy in steel sector are indicative of good international industry practice as reflected in relevant standards of countries with recognized regulatory frameworks and are given in Tables 1,2,3 & 4. *

*The above tables (1&2) are taken from the guidelines prepared jointly by the

International Finance Committee ( IFC ) and World Bank Group and released in April, 2007

*The above tables (3&4) are taken from the guidelines prepared jointly by the

International Finance Committee ( IFC ) and World Bank Group and released in April, 2007

Examples of New Technologies for Using Fines

There are newer techniques of iron production that could utilize ore fines and slimes. Apart from Corex (already in use by M/S. Jindal) and Finex( projected by M/S. POSCO for Orissa) processes, the Fastmet process of Midrex/Kobe for sponge production and the ITmk3 ( of Kobe steel ) for production of iron nugget using rotary hearth furnace (RHF) from ore fines & slimes as well as plant wastes (making use of pellets ) and the Oxycup process of Germany ( using ferruginous plant wastes) are interesting processes for making use of the fines / slimes that are practically unused, as well as iron bearing wastes generated in steel plants. The gasification of coal and use of the synthetic gas ( Syngas ) for producing sponge iron is another technology (e.g. combination of Lurgi process for Syngas and Midrex process for Sponge, at the Jindal plant in Orissa) that is worth studying in the context of the Indian condition

Making High Value Products from By-products – Some Examples

There are also efforts to use wastes generated in steel plants to produce value-added products. The higher usage of fly ash or BF slag in the blended cements is restricted by the low pozzolanic and/or latent hydraulic activity, consequently resulting in slower development of compressive strength as compared to ordinary portland cement (OPC). Mechanical activation by high-energy milling is found to improve the reactivity of the blended cement constituents, viz. the clinker, fly ash and the slag Increased pozzolanic reactivity of fly ash through mechanical activation by attrition as well as vibratory milling results in a denser product. In recent times, manufacturers are attempting to use very high volume (>50%) fly ash in cement, known as HVFA cement. This would reduce pollution by using a polluting waste product, i.e. fly ash from the thermal power plants. Similarly intensive research is continuing today to enhance the quantity of blast furnace slag in cement, by enhancing the surface area of reactivity through attrition. It has also been observed in research laboratories that upto 80% clinker can be replaced by attrition milled blast furnace slag with superior or similar compressive strength as observed for typical commercial cement, containing only about 35% slag. Additionally, there are efforts to use BOF slag for high quality cements, by removing phosphorus; in view of its high free lime content. Some of these processes are commercialized elsewhere.

An interesting development is the recovery and use of ZnO produced in steel plants. A high amount (over 25 mtpy world-wide) of zinc oxide (ZnO) dust is generated each year by the iron and steel industries; the ZnO if recovered can be used in developing a low cost reagent for de-sulphurising hot metal, as shown recently. This can bring in a saving in expensive magnesium, leading to increased iron yield. Another solid by-product, after the acid pickling (to remove oxide scales) is primarily iron chloride that is used to produce Iron Oxide; which in turn can be used for manufacturing a variety of electronic grade ferrites and pigment.

Conclusion

The manufacturing of steel in India is now poised for a global leadership role, next only to China’s. At this point, one needs to take all possible measures for keeping under control, any possible environmental degradation. In particular, the reduction of carbon dioxide is of paramount importance and regular monitoring of the same, along with introduction of newer measures need to be examined from time to time.

Conservation of iron ore resources is critical to the sustainability of the iron and steel industry in India. For doing so, uses of low grade ores in conjunction with beneficiation processes are needed. Further, the plant generated iron bearing materials, the fines and super-fines generated in mines are to be used. For this to happen, the newer iron-making & steel-making processes, along with agglomeration techniques are to be examined seriously.

Increasing use of the by-products / waste-materials in iron and steel plants in the manufacture of value-added products is necessary for enhancing the economic viability of Indian plants.